Introduction

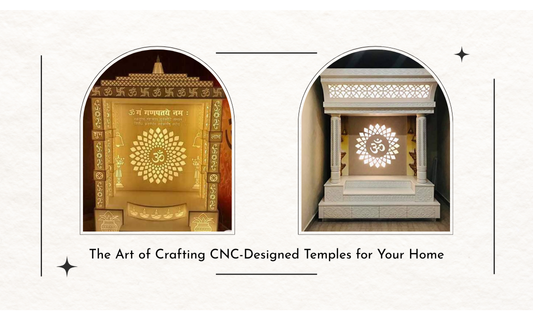

Temples are not just structures; they are sacred spaces that represent faith, devotion, and the connection to the divine. At Aastha Mandir, we specialize in creating CNC-designed wooden temples that offer the perfect blend of tradition and modernity. In this blog, we will explore the benefits, challenges, advantages, disadvantages, and solutions in designing and crafting these beautiful mandirs.

Benefits of CNC-Designed Temples

-

Precision and Detail

CNC machines offer unrivaled precision, ensuring that every detail of the temple is meticulously crafted. This means cleaner lines, better finishes, and intricate designs that might be difficult to achieve by hand. -

Customization

One of the greatest advantages of CNC technology is the ability to create highly customizable designs, making it easier to create temples in various sizes, shapes, and styles to fit the unique needs of your space. -

Durability

CNC temples are crafted from high-quality wood, ensuring longevity. The cuts are consistent, resulting in temples that stand the test of time while maintaining their aesthetic appeal.

Challenges in CNC Temple Crafting

-

High Initial Investment

Setting up CNC technology involves a significant investment in machinery and software, making it a costly initial setup. -

Skill and Training

Though CNC machines are automated, the skill required to program and operate them is still substantial. A team needs to be well-trained to ensure that the final product meets expectations. -

Material Selection

Choosing the right materials for CNC cutting is crucial for achieving the best results. The wrong wood type can result in difficulties during the carving process or compromise the quality of the final product.

Advantages of CNC-Designed Temples

-

Increased Accuracy

CNC technology offers superior accuracy, allowing for more intricate designs and patterns, which is critical for creating detailed religious motifs. -

Consistency

CNC machines replicate the same design multiple times with consistency. For customers, this means each product, whether mass-produced or custom-made, has uniform quality. -

Faster Production Times

Automated processes speed up production, which results in quicker delivery times for customers without compromising on quality.

Disadvantages of CNC-Designed Temples

-

Higher Cost of Customization

While CNC technology offers a lot of flexibility in design, it may come with a higher cost for custom orders compared to traditional handcrafted methods. -

Limited to Machine Capabilities

Some complex designs may not be possible with CNC machines alone, as they are limited to certain capabilities and precision. -

Dependency on Technology

Over-reliance on technology could lead to issues if there’s a malfunction with the CNC equipment, causing delays.

Solutions to Overcome Challenges

-

Strategic Investment in Technology

Investing in a high-quality CNC machine that delivers precision can lead to long-term benefits, including improved product quality and efficiency. -

Ongoing Training

Continuing education for the workforce ensures they stay updated on the latest technology trends and improvements. -

Quality Control

Implementing strict quality control measures and regular maintenance checks helps mitigate any issues with machinery and materials, ensuring flawless results.

Conclusion

CNC-designed temples offer unmatched precision, beauty, and customization. Despite some challenges, such as high initial costs and dependence on technology, the advantages far outweigh the drawbacks. At Aastha Mandir, we embrace innovation while staying rooted in tradition, crafting temples that inspire peace, faith, and divine connection.